DESCRIPTION

Sterisheet sterilization wraps are high quality Sterile Barrier Systems for CSSDs in hospitals and clinics. Our production is 100% healthcare dedicated. Sterisheet products are delivered with confidence and pride to the market and are used in thousands of hospitals around the world.

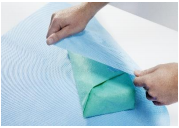

Interleaved Solution

Ready to use sterilization wraps for double sequential wrapping which is the recommended packaging practice. The best possible combination of microbacterial protection and resistance. Adopt to weight of tray to be packed, sterilization method, transport and storage conditions

Suitable for Following Sterilization Methods:

Steam

EO

Low Temperature Steam Formaldehyde (LTFS)

Benefits of Interleaved Solution

Composition

The best products features taken from cellulose-based and SMS material. Cellulose-based material to secure the best possible bacterial barrier and prevention of wet pack whereas SMS layer provides exceptional mechanical protection

Products:

INTERLEAVED 160 SOFT G/340 SMS B

INTERLAVED 160 SOFT G/347 SMS B

INTERLAVED 160 SOFT G/355 SMS B

Sterisheet interleaved combines 2 different sterilization wraps together:

Inner layer:

Sterisheet 160 Soft – Original wrapping material

Composition – 97 – 100% Cellulose, water repellent and biodegradable. Material with the highest bacterial filtration efficiency

Grammage – 60 gsm

Color – green

Cellulose-based material used as the inner layer helps to prevent or reduce wet pack issues. (Residual water after steam sterilization can be possible vehicle of microorganisms.)

Outer layer:

Sterisheet SMS

Composition – 100% synthetic polypropylene fibers

Grammage – 40 gsm, 47 gsm, 55 gsm

Color – blue

Using SMS as an outer layer guarantee physical protection of the pack, ready to withstand demanding handling or transport conditions

Application:

For small and medium or heavy size trays, instrument kits

Sizes Available:

Following are standard sizes available for all our customers’ needs. Choose standard sizes to optimize your costs. Other sizes are also available upon request.

60×60 cm 90×90 cm 120×120 cm

75×75 cm 100x100cm 137×137 cm

Product Properties:

Mechanical protection and bacterial barrier properties are tested carefully. Our internal laboratory provides complex tests on all of our products. Together with tests conducted by external independent laboratories we secure the best possible results on Sterisheet products.

Mechanical Properties:

Preservation of pack integrity from closure till the point of use depends on the materials resistance to tearing, puncturing, breaching stresses generated all along the distribution, handling and storage with the hospital. Any mechanical weaknesses will increase the risks of event related ingression of microorganism into the pack. Excellent mechanical properties will provide you additional safety while using our materials. Optimal strength and resistance brought in every sheet

Bacterial Properties:

Sterilization wraps must prevent microorganisms’ ingression inside the package. To reach this performance, different types of testing have to be performed on the products to reproduce both kind of ingression vehicles possible:

- Airborne ingression

- Waterborne ingression

Compliance to Standards:

Sterisheet products range is classified Class I Medical Device according to the European Medical Device Directive (MDD). Its CE marking illustrates the relevant compliance. Sterisheet products are conform with standards below:

EN ISO 11607-1:2017

EN 868-2:2017

Our Wraps Manufacturing Third Part Certification:

ISO 13485 standard

Packaging Prior to Use:

Sheets display is optimized by adjusted folding depending on the size and type of the product. We have tested carefully the best solution to ensure the most convenient handling for end users.

- PRIMARY TRANSPORT PACKAGING

Number of sheets is maximized and wrapped in transparent polyethylene bag with quick product ID. - SECONDARY TRANSPORT PACKAGING

Secondary packaging is a neutral brown color cardboard box providing transportation stress resistance.

Labelling:

Product traceability is fully insured through labelling according regulations on each transport packaging.

Storage Conditions:

Sterimed recommends the following storage conditions for best performance of sterilization wraps: Storage in a cool, dry location away from direct exposure to natural light, strong artificial light & UV sources. Cardboard boxes should never be stored in direct contact with the floor. Storage of the products shall be done in areas that are not subject to extreme temperature changes such as in contact with heated objects, vents or cold walls. As per AAMI ST79 “Comprehensive guide to steam sterilization and sterility assurance in health care facilities” recommendations: Before use, holding packaging materials at room temperature (20°C to 23°C) and at a relative humidity ranging from 30% to 60% for a minimum of 2 hours is a good practice for optimum use performances.

Use by Date:

Provided the above storage conditions are met, the upper limit of the time interval during which the performance characteristics of the sterile barrier system are demonstrated is 5 years of the manufacturing date.

Environmental Impact & Waste Management:

STERIMED Infection Control is committed to the protection of the environment and the communities it belongs to.

STERISHEET 160 SOFT CREPE > 95 % renewable content

Wood pulp used for production is sourced from renewable sustainable well managed forest sources.

Disposal as per local regulations after use

"*" indicates required fields