gke Steri-Record® Process Challenge Devices

to monitor steam sterilization processes

Application

In the sterilizer standards EN 285 and EN 13060 type tests are described, e.g. BD-Test or Helix Test according to EN 867-5. They are only testing the standard requirements of the sterilizers with-out any relation to the load.

They are quite often used as so-called batch monitoring systems and sold as various test sys-tems on the market to monitor the load. However, these tests have no relation to the load. Therefore, it cannot be automatically concluded that difficult loads can be sterilized successfully. A monitoring system for the load must not be adopted to the sterilizer but must represent the load.

This adoption can be achieved in two ways:

Process Monitoring System (PMS):

The sterility of the load is assured if the sterilization process has been validated with a worst-case load. The continuous monitoring of the load shall be carried out with a test system which monitors the maximum performance of the sterilizer. Modern sterilizers provide much better performance than the required type tested mentioned above. For this purpose gke offers a variety of different PCDs (process challenge devices) with increasing sensitivities to monitor the process at highest level. These test devices are called process monitoring systems (PMS).

Batch Monitoring System (BMS):

If the characteristics of the load to be sterilized are known, a PCD can be designed and validated to be more difficult to sterilize than the defined load using the method according to DIN 58921 (medical device simulator). gke has already tested several typical loads with the method according to DIN 58921 and offers special PCDs for Tattoo, Dental and Ophthal-mic loads. For these test systems separate data sheets with detailed information are available.

gke Steri-Record® Process Challenge Devices to monitor steam sterilization processes

Application

In the sterilizer standards EN 285 and EN 13060 type tests are described, e.g. BD-Test or Helix Test according to EN 867-5. They are only testing the standard requirements of the sterilizers with-out any relation to the load.

They are quite often used as so-called batch monitoring systems and sold as various test systems on the market to monitor the load. However, these tests have no relation to the load. Therefore, it cannot be automatically concluded that difficult loads can be sterilized successfully. A monitoring system for the load must not be adopted to the sterilizer but must represent the load.

This adoption can be achieved in two ways:

Process Monitoring System (PMS):

The sterility of the load is assured if the sterilization process has been validated with a worstcase load. The continuous monitoring of the load shall be carried out with a test system which monitors the maximum performance of the sterilizer. Modern sterilizers provide much better performance than the required type tested mentioned above. For this purpose gke offers a variety of different PCDs (process challenge devices) with increasing sensitivities to monitor the process at highest level. These test devices are called process monitoring systems (PMS).

Batch Monitoring System (BMS):

If the characteristics of the load to be sterilized are known, a PCD can be designed and validated to be more difficult to sterilize than the defined load using the method according to DIN 58921 (medical device simulator). gke has already tested several typical loads with the method according to DIN 58921 and offers special PCDs for Tattoo, Dental and Ophthalmic loads. For these test systems separate data sheets with detailed information are available.

Product Description

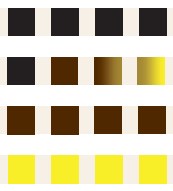

The gke Steri-Record® Compact-PCD® consists of an external plastic casing with an internal stain-less steel tube and capsule holding the indicator. The four colour-coded PCDs are available with two constructions:

Round Version with Stainless Steel Bracket

This PCD can be put vertically on a loading rack or placed horizontally on the bracket

Oval Version (Green and Orange)

This PCD can be placed horizontally on the flat side of the PCD, suitable for small sterilizers (2.5 cm height)

All PCDs are re-usable and can be used for a considerable number of sterilization cycles.

Performance Characteristics

The gke PCDs are type 2 indicator systems according to EN ISO 11140-1, consisting of a “specific test load” (Process Challenge Device = PCD) and “indicator” (indicator strip). They have been validated from a laboratory accredited according to the standard EN ISO 17025 (test reports on request).

gke offers a variety of PCDs with different levels of difficulty. Using a test with the highest level which will still pass in a validated process the sterilizer is always tested at its limits. Failures that are not detected with standard methods will now be visible and the maximum possible safety to test sterilization processes can be guaranteed. If a process has been validated with a defined load and a suitable test system, this method secures the sterilization at the most difficult locations.

This is not possible by only recording the physical data with documentation, e.g. with a printer.

The identification of a suitable PMS to monitor sterilization has to be verified during process validation depending on the load.

The gke representatives support in the selection of the test system depending on the load.

Performance Characteristics

The gke PCDs are type 2 indicator systems according to EN ISO 11140-1, consisting of a “specific test load” (Process Challenge Device = PCD) and “indicator” (indicator strip). They have been validated from a laboratory accredited according to the standard EN ISO 17025 (test reports on request).

The gke PCDs are type 2 indicator systems according to EN ISO 11140-1, consisting of a “specific test load” (Process Challenge Device = PCD) and “indicator” (indicator strip). They have been validated from a laboratory accredited according to the standard EN ISO 17025 (test reports on request).

gke offers a variety of PCDs with different levels of difficulty. Using a test with the highest level which will still pass in a validated process the sterilizer is always tested at its limits. Failures that are not detected with standard methods will now be visible and the maximum possible safety to test sterilization processes can be guaranteed. If a process has been validated with a defined load and a suitable test system, this method secures the sterilization at the most difficult locations.

This is not possible by only recording the physical data with documentation, e.g. with a printer.

The identification of a suitable PMS to monitor sterilization has to be verified during process validation depending on the load.

The gke representatives support in the selection of the test system depending on the load.

Performance Characteristics

The gke PCDs are type 2 indicator systems according to EN ISO 11140-1, consisting of a “specific test load” (Process Challenge Device = PCD) and “indicator” (indicator strip). They have been validated from a laboratory accredited ac-cording to the standard EN ISO 17025 (test reports on request).

gke offers a variety of PCDs with different levels of difficulty. Using a test with the highest level which will still pass in a validated process the sterilizer is always tested at its limits. Failures that are not detected with standard methods will now be visible and the maximum possible safety to test sterilization processes can be guaranteed. If a process has been validated with a defined load and a suitable test system, this method secures the sterilization at the most difficult locations.

This is not possible by only recording the physical data with documentation, e.g. with a printer.

The identification of a suitable PMS to monitor sterilization has to be verified during process validation depending on the load.

The gke representatives support in the selection of the test system depending on the load.

1. PMS Compact-PCD®, colour: green

This PMS Compact-PCD®, colour: green, represents a challenging test concerning air removal and steam penetration that can be used for routine monitoring of simple hollow devices, tubes, porous loads and solid instruments. However, this PMS is less demanding regarding air removal and steam penetration than the hollow load test described in EN 867-5.

2. PMS Compact-PCD®, colour: orange

The PMS Compact-PCD®, colour: orange, simulates the hollow load test according to EN 867-5. This type test is included in the standard for large sterilizers (EN 285) as well as in the standard for small class B sterilizers (EN 13060).

The standard EN 867-5 describes a test cycle with 9 injections of steam to 950 mbar. In this test cycle the hollow load test will be successfully penetrated, if a vacuum of 450 mbar will be reached in between each steam pulse.

3. HDH-PMS Compact-PCD®, colour: red

The HDH-PMS Compact-PCD®, colour: red, (High Demand Hollow) is used for routine monitoring of complex instruments or long tubes, whereas the hollow load test according to EN 867-5 is not anymore sufficient.

To successfully penetrate the gke-HDH-PMS in the same test cycle a vacuum of at least 210 mbar is necessary.

4. VHDH-PMS Compact-PCD®, colour : brown

The VHDH-PMS Compact-PCD®, colour: brown, (Very High Demand Hollow) makes increasing demands on the air removal performance. The test cycle according to EN 867-5 with 9 injections of steam requires vacuum cycles of at least 160 mbar to successfully penetrate the VHDH-PMS.

These data are only valid under laboratory conditions using a reproducible process in a test sterilizer according to EN ISO 18472. All other variables that affect the air removal and steam penetration are strictly defined in such a program and must remain unchanged in all test cycles.

Under real sterilization conditions the differences in performance between type test according toEN 867-5 and the gke HDH-PMS or gke VHDH-PMS may change considerably because day-to-day programs differ from the above mentioned test cycle. Usually less but deeper vacuum cycles are used.

Operation Description

Operation Description

Two indicator strips can be selected according to the program used and are available with different stated values:

1. 134°C, 3 min or 121°C, 15 min

(standard cycle)

2. 134°C, 18 min (prion cycle)

If all four bars of the chemical indicator turn from yellow (standard cycle) /pink (prion cycle) to black it is an indication of sufficient steam penetration inside the PCD.

Key Benefits

Key Benefits

Order Information

Each start-up kit contains of a Compact-PCD and 100 integrating indicator strips for standard steam sterilization processes. All test devices are also available separately. The indicator strips are available as refill packs for standard and prion steam sterilization processes and also contain a sealing kit for the screw cap.

Order Information

Each start-up kit contains of a Compact-PCD and 100 integrating indicator strips for standard steam sterilization processes. All test devices are also available separately. The indicator strips are available as refill packs for standard and prion steam sterilization processes and also contain a sealing kit for the screw cap.

1. Start-up kit and process challenge devices / Process monitoring systems (PMS)

| Art.-No.* | Product Code | Quantity | Content | Stated Value | Application |

|---|---|---|---|---|---|

| 211-253 | C-S-PM-SHL-RCPCD-KIT | 1 + 100 |

Compact-PCD® round sec-tion (colour: green), integrating indicator strips |

134° C, 3 min 121°C, 15 min |

for simple hollow devices, porous loads and solid instruments |

| 211-254 | C-S-PM-SHL-OCPCD-KIT | Compact-PCD® oval section (colour: green), integrating indicator strips |

|||

| 200-020 | PM-HL-RCPCD | 1 | Compact-PCD® round sec-tion (colour: green) | – | |

| 200-024 | PM-SHL-OCPCD | Compact-PCD® oval section (colour: green) | |||

| 211-263 | C-S-PM-HL-RCPCD-KIT | 1 + 100 |

Compact-PCD® round sec-tion (colour: orange), integrating indicator strips |

134° C, 3 min 121°C, 15 min |

Hollow Load Test according to EN 867-5 |

| 211-264 | C-S-PM-HL-OCPCD-KIT | Compact-PCD® oval section (colour: orange), integrating indicator strips |

|||

| 200-021 | PM-SHL-RCPCD | 1 | Compact-PCD® round sec-tion (colour: orange) | – | |

| 200-026 | PM-HL-OCPCD | Compact-PCD® oval section (colour: orange) | |||

| 200-029 | PM-HDH-RCPCD | Compact-PCD® round sec-tion (colour: red) | with higher require-ments than EN 867-5 | ||

| 200-030 | PM-VHDH-RCPCD | Compact-PCD® round sec-tion (colour: brown) | with extremely high requirements than EN 867-5 |

2. Refill packs indicator strips

| Art.-No.* | Product Code | Quantity | Content | Stated Value | Application |

|---|---|---|---|---|---|

| 211-252 | C-S-PM-SV1 | 250 | Refill pack Integrating indicators + 1 sealing kit |

134° C, 3 min 121°C, 15 min |

Indicator strips for all gke PMS in standard steam sterilization processes |

| 211-255 | 500 | ||||

| 211-211 | C-S-PM-SV2 | 100 | 134° C, 18 min | Indicator strips for all gke PMS in steam sterilization processes (“prion programs”) |

|

| 211-212 | 250 | ||||

| 211-215 | 500 |

To all article numbers a 3-digit alpha code is added. The additional letter code refers to the language and/or customized and plug version. It is only added on the outside label, the inside of the pack is identical to the article numbers on the above tables.

"*" indicates required fields